75 Years of Unverferth Manufacturing

We've been building better together since 1948. Follow our rich history and see how we've grown over the past 75 years.

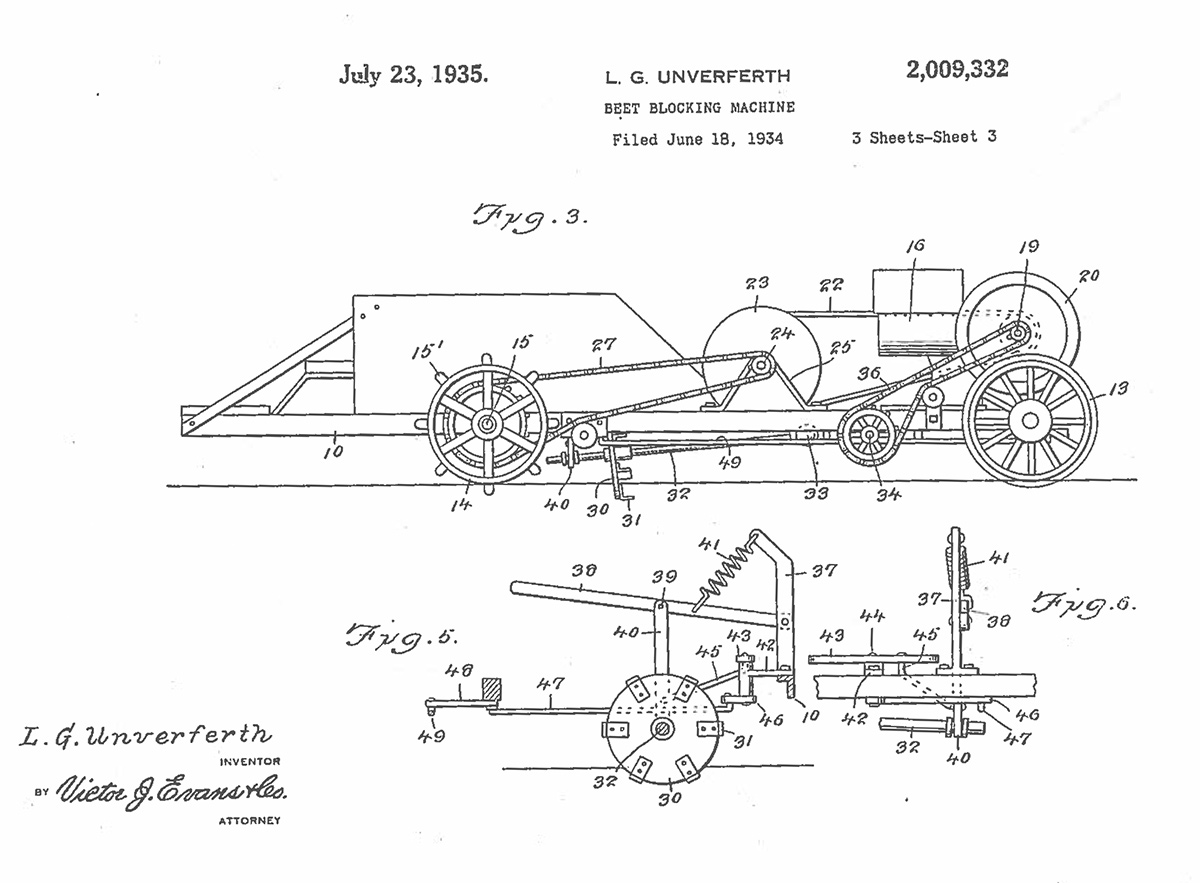

A father son duo, Lawrence G. and Richard Unverferth, refine and test a mechanical beet-thinning tool called the Beet Blocker for the family farm. In the same year, a patent issues for this product.

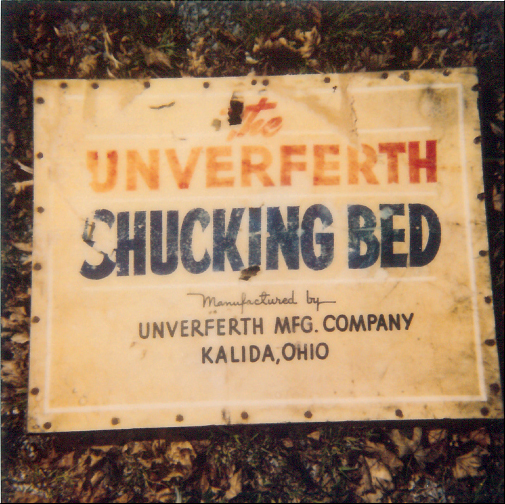

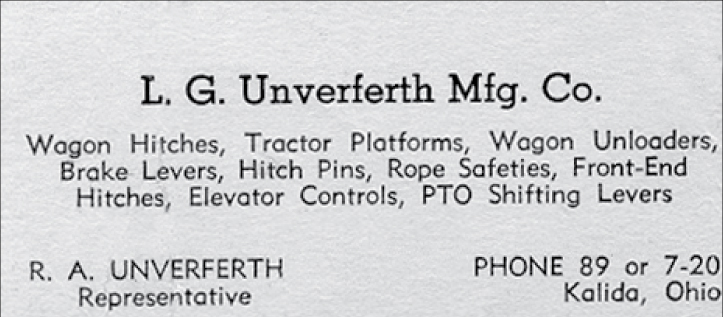

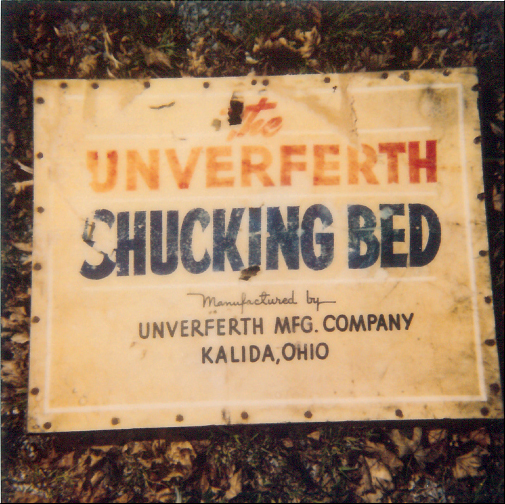

Richard, teamed with his father, Lawrence, open L.G. Unverferth Manufacturing with a loan from family members using their war bonds. The company begins by manufacturing combine shucker control levers.

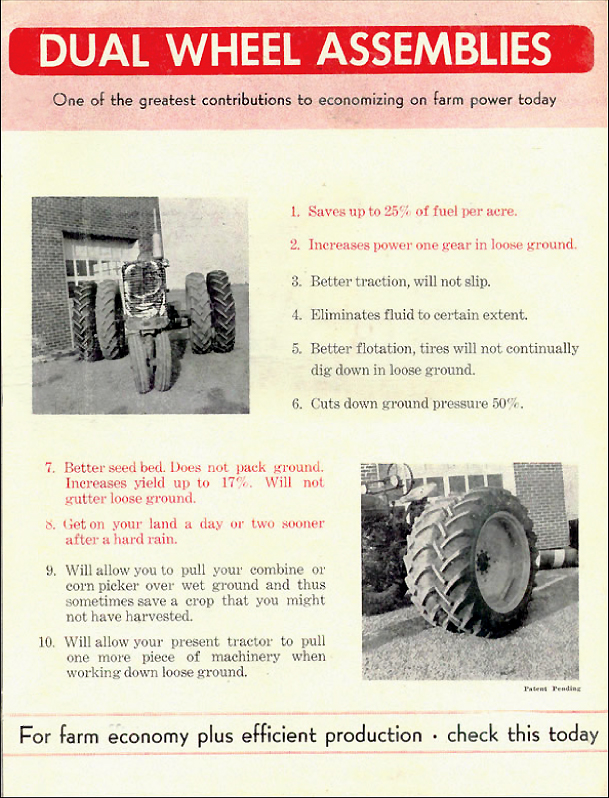

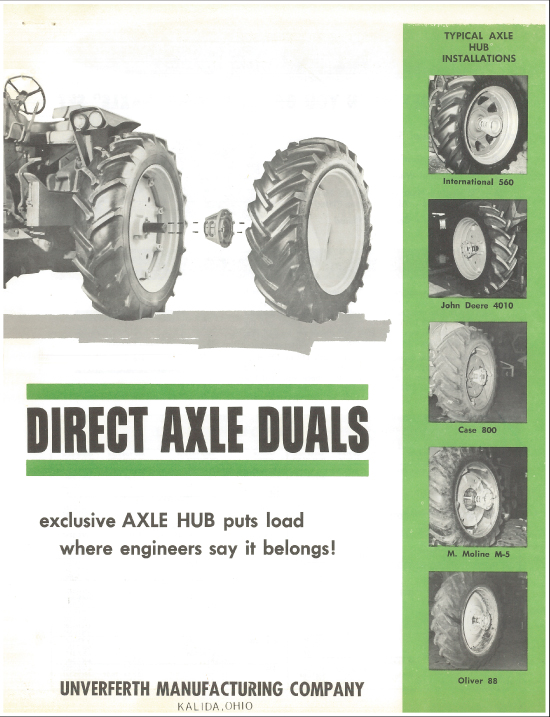

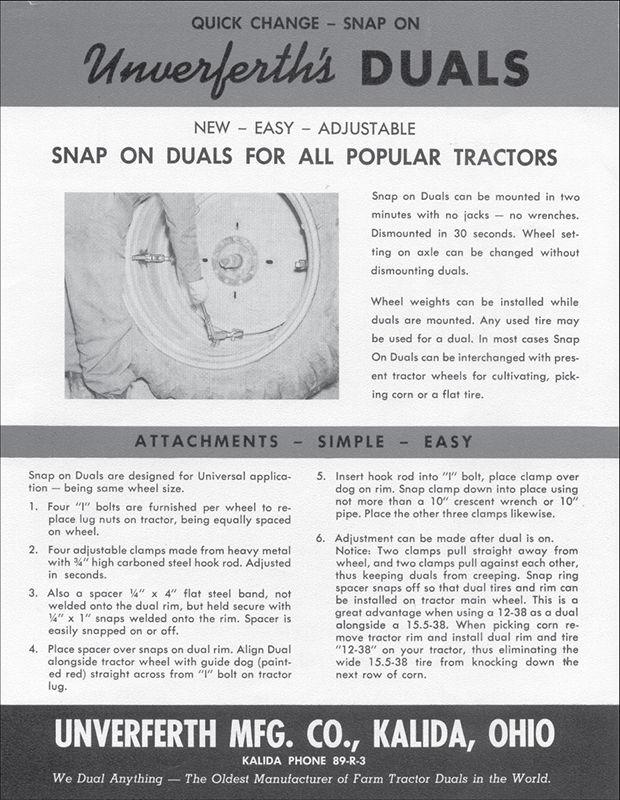

The Unverferth duo introduce bolt-on, stovepipe hat-shaped wheel extensions for adding dual wheels to tractors.

The company begins manufacturing dual wheels, all from the family's farm. These products firmly establish Unverferth in the agricultural wheel business, which continues today.

A patent issues for the mounting of dual agricultural wheels.

The construction of a new manufacturing facility and corporate offices are complete at the present-day location in Kalida, Ohio. The company incorporates as Unverferth Mfg. Co., Inc. and introduces Turn-Rite running gears.

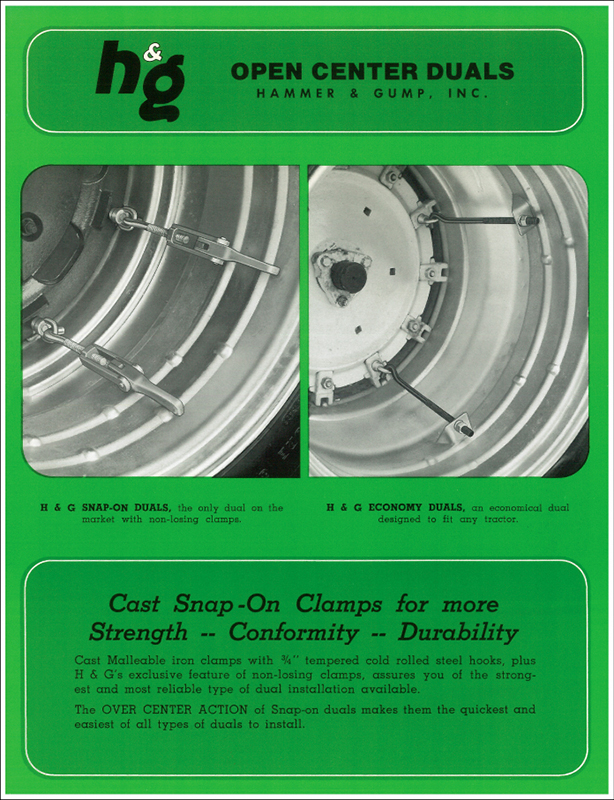

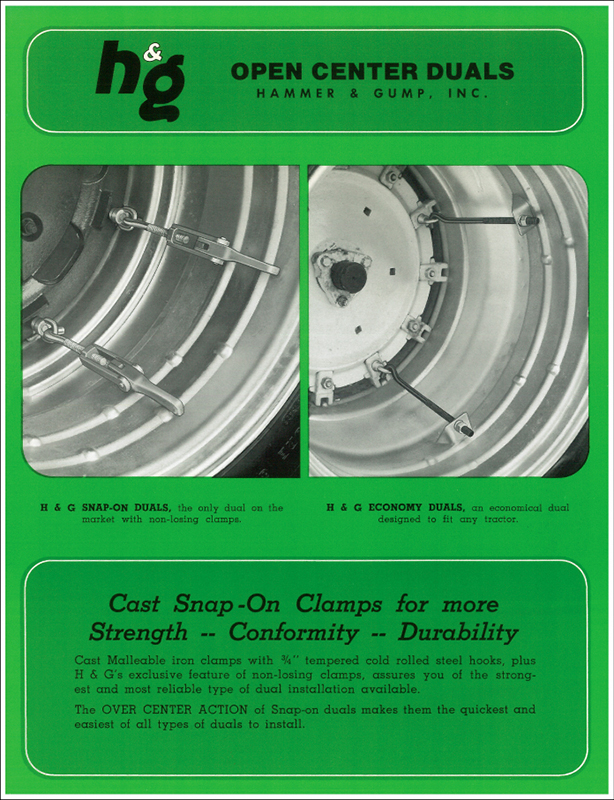

The company purchases Hammer and Gump, a nearby competitor of dual agricultural wheels. In the same year, a patent issues for snap-on-style dual agricultural wheels.

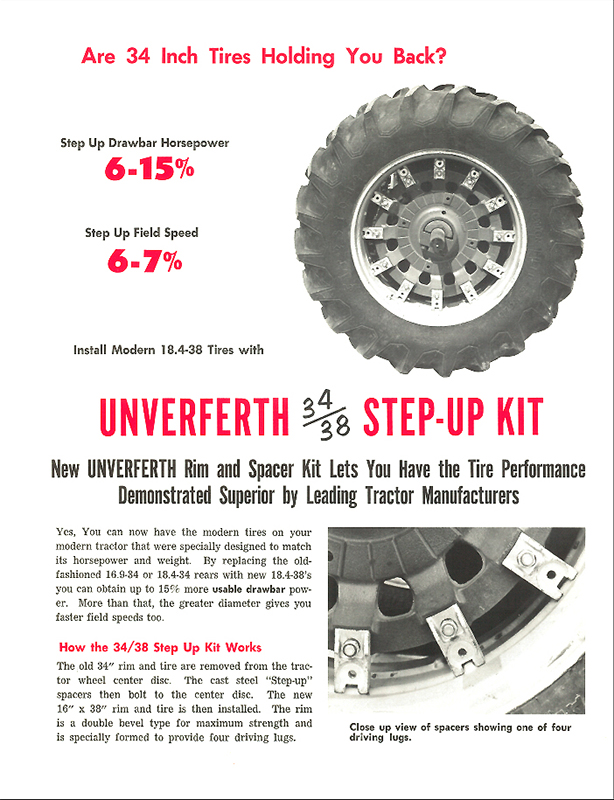

The introduction of step-up lugs allow farmers to go from 34" rims to 38" rims economically. A patent issues in 1970.

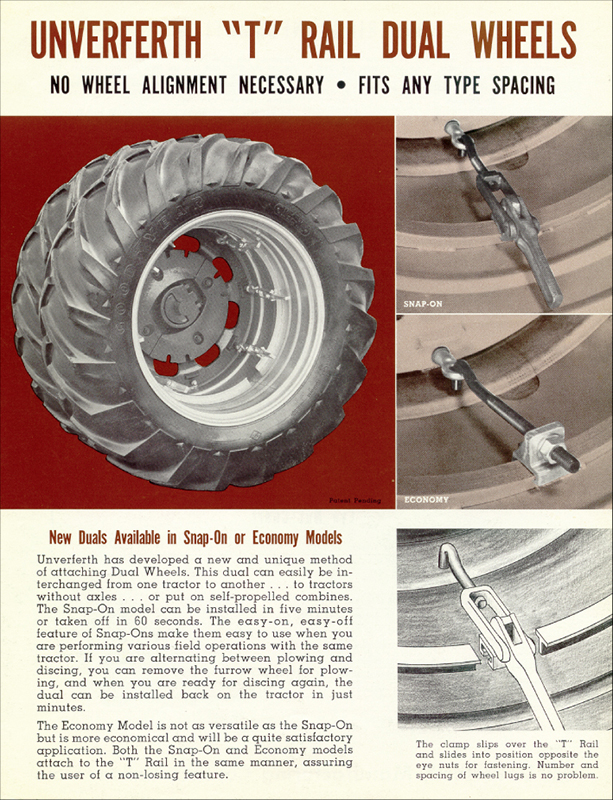

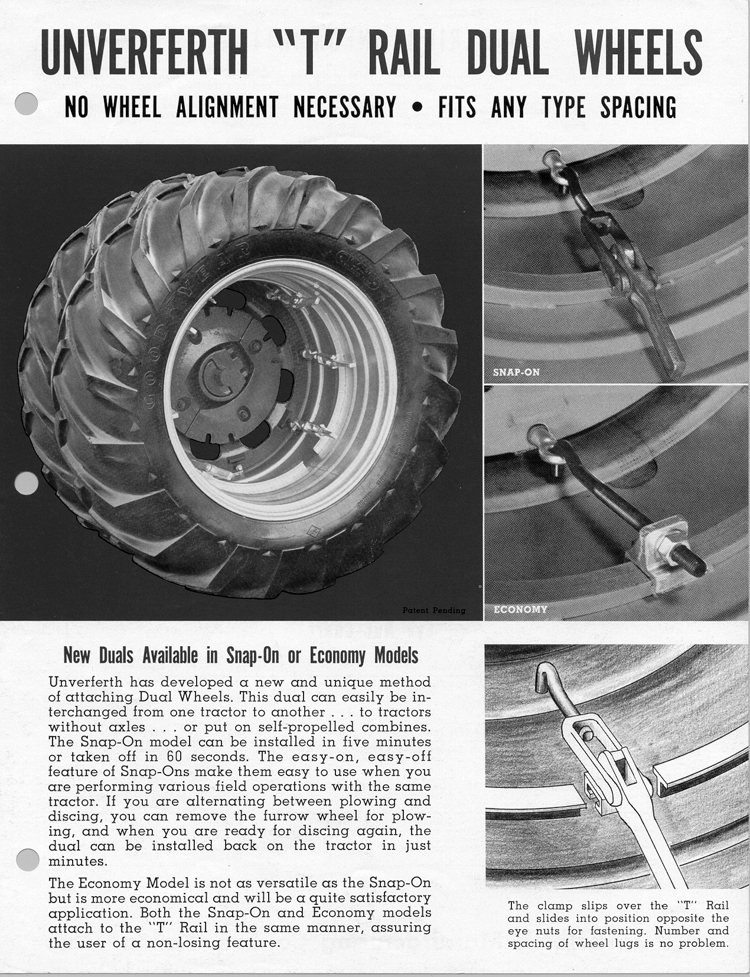

The introduction of the T-Rail dual wheel system for easy on and easy off dual wheel mounting. A patent issues in 1971.

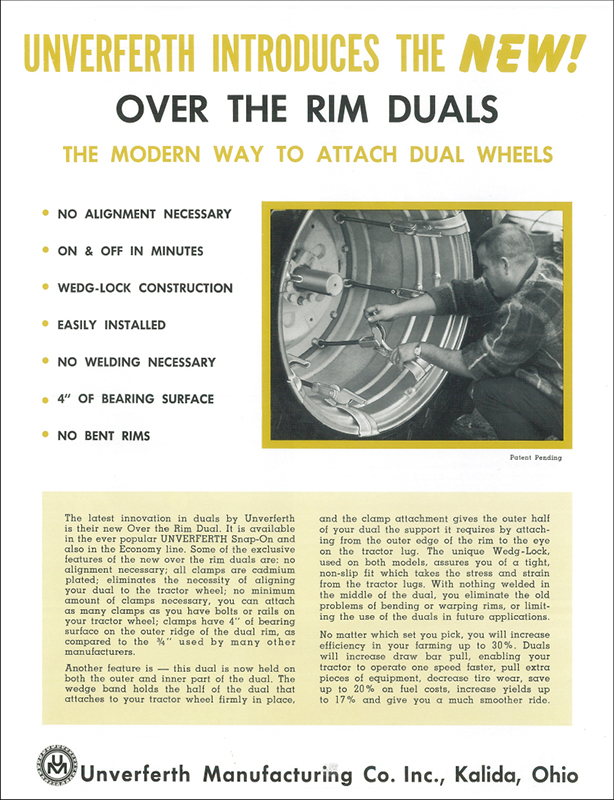

The launch of Over-The-Rim dual wheels bring another mounting style to the marketplace.

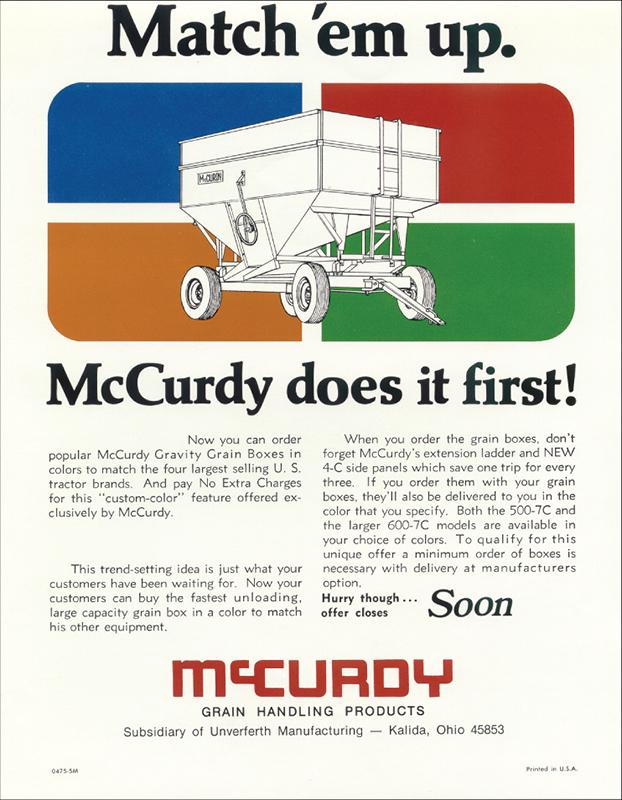

The acquisition of McCurdy Manufacturing in Ada, Ohio, adds gravity boxes and box augers to the product mix. In the same year, a patent issues for a Tandem Axle running gear.

Unverferth Mfg. celebrates its 25th Anniversary.

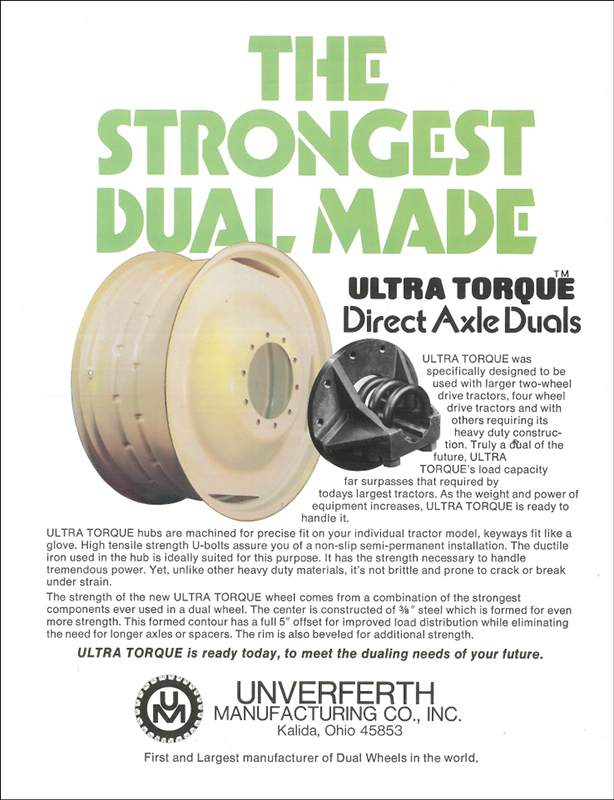

The introduction of Ultra-Torque direct-axle duals.

The Circoloc dual wheel system launches, and the company purchases a patent for the Towmobile trailer which hauls a tractor behind a pickup truck. A patent for the Circoloc dual wheel system issues in 1985.

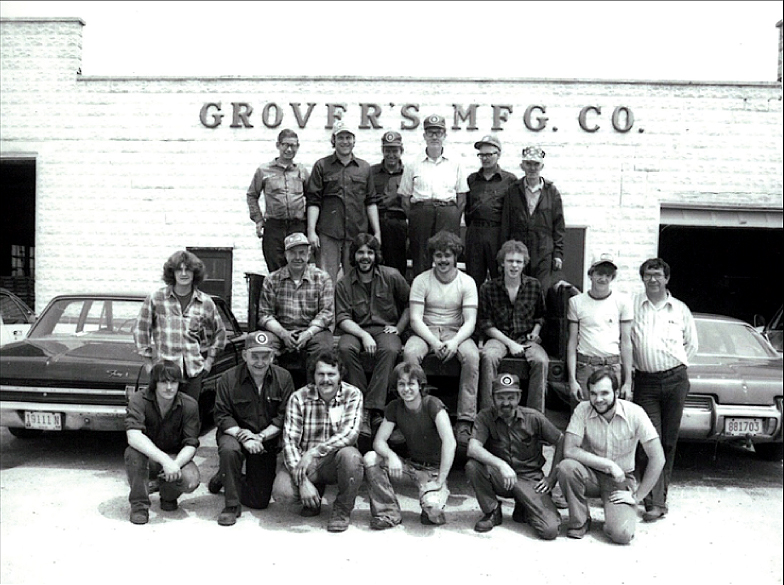

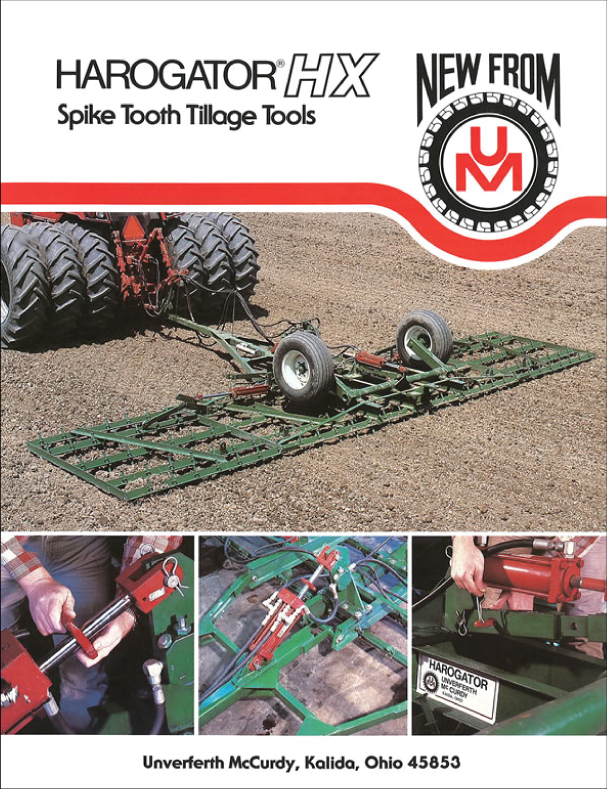

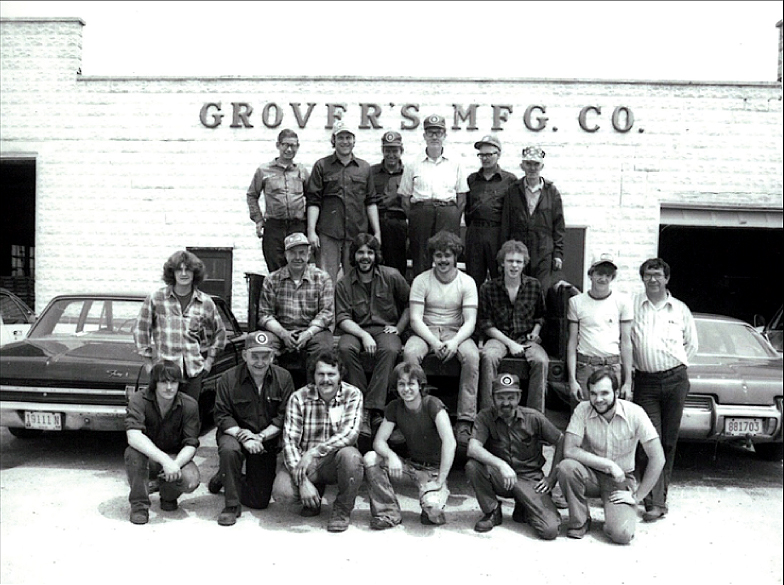

Unverferth purchases Grover Manufacturing Company of Luckey, Ohio, which produces the popular Harogator tillage tool.

The company establishes the first sales branch in Albany, Georgia.

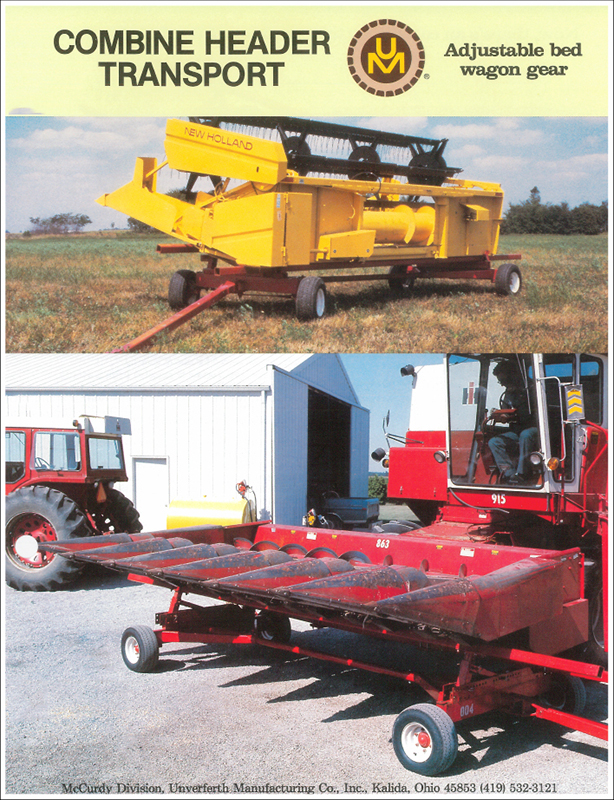

The introduction of Unverferth header transports give farm operations a reliable way to transport their combine head or platform.

The introduction of the Culti-Planter tillage tool permits one-pass tillage and plant operation. A patent issues in 1986.

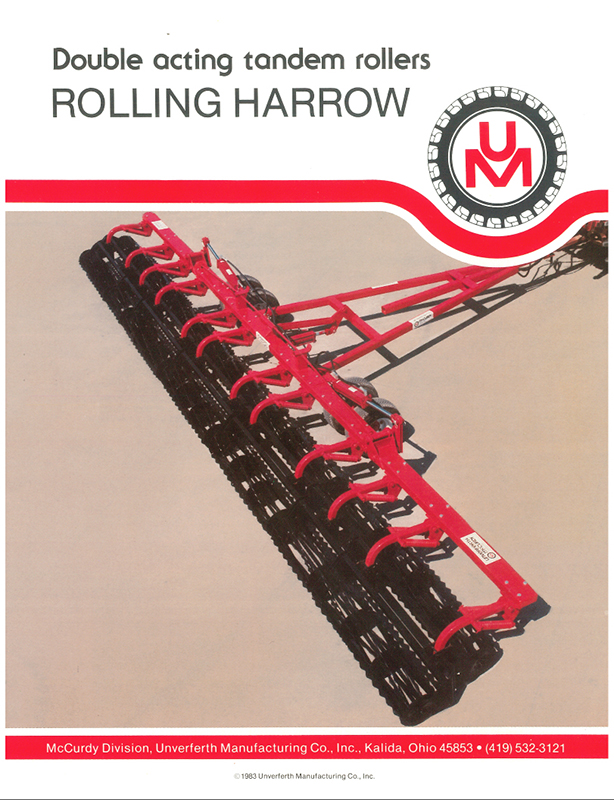

Unverferth releases the innovative Rolling Harrow soil conditioner which continues to be a popular product today.

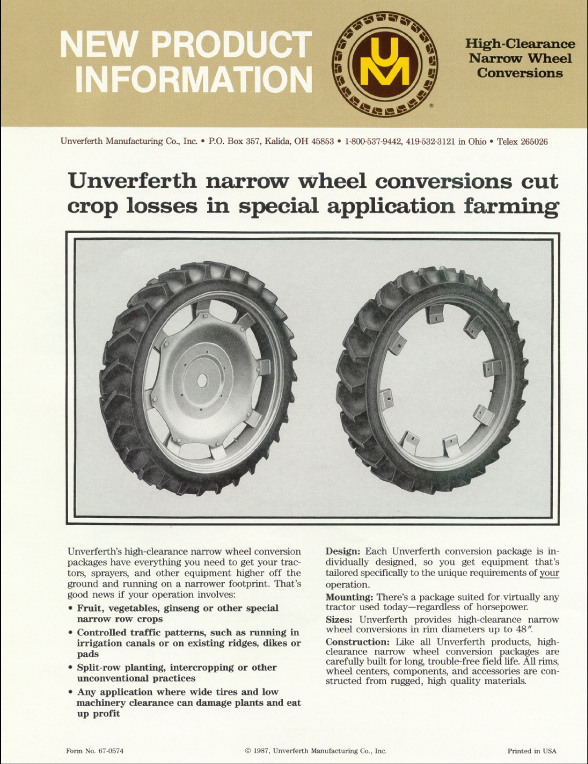

The company introduces narrow wheel conversions along with the Round-About bale wrapper which earns a patent in 1990.

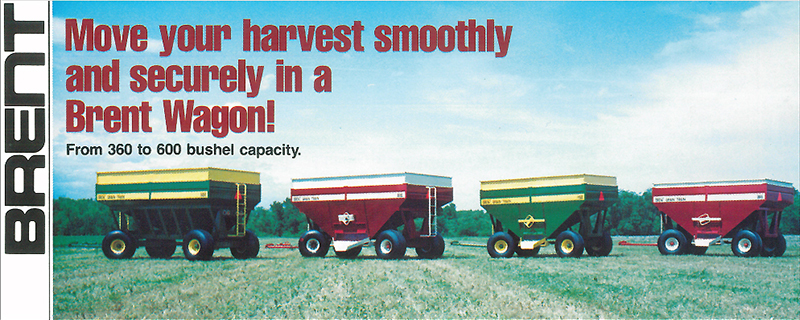

Unverferth purchases Brent Industries in Shell Rock, Iowa, and adds grain carts and large wagons to the company portfolio. This acquisition expands manufacturing into the heart of the Midwest where a state-of-the-art facility stands today.

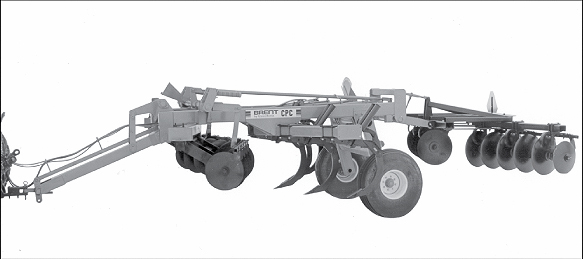

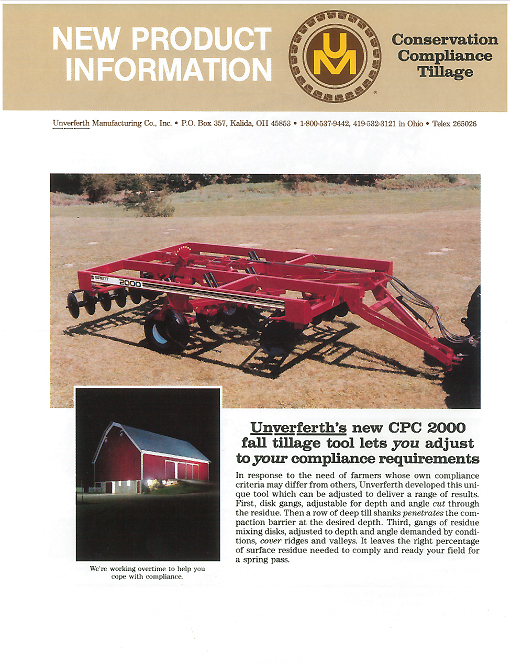

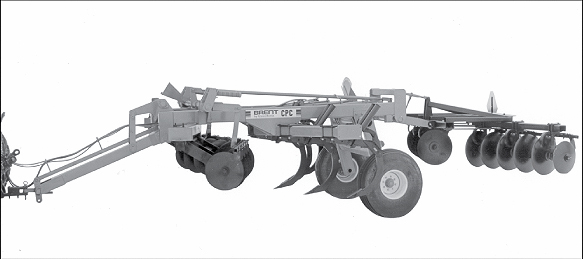

The Brent CPC 2000 disk ripper debuts at the Farm Progress Show in Amana, Iowa, and a patent issues in 1992. The second sales branch opens in Fresno, California, to support robust wheel sales. In 1995 the branch moves to Tulare.

Unverferth purchases Rawson Coulters in Farwell, Michigan, which focuses on toolbar-mounted three coulter tillage implements. In the same year, the Unverferth Rawson Zone-Builder deep-tillage tool launches.

The company acquires a fierce competitor, Kill Brothers Company, in Delphos, Ohio. Production continues in Delphos today where a state-of-the-art manufacturing facility stands.

A new sales branch opens its doors in Jamestown, North Dakota. This branch location moves to Tower City, North Dakota, in 1998 and then to the present-day location of Casselton in 2008.

To better serve customers in the upper northwest, the company establishes a new sales branch in North Powder, Oregon.

A new sales branch opens in Woodstock, Ontario, that relocates to Ingersoll, Ontario, in 2010.

Unverferth Mfg. celebrates its 50th Anniversary. In the same year, the company introduces the Brent Avalanche double-auger grain cart with a pivoting unloading auger design and also opens the Kearney, Nebraska, sales branch.

The company purchases assets of Hecla Mfg. in Hecla, South Dakota, which includes skid-steers and attachments. In the same year, the Town & Country, Ltd brand debuts.

Unverferth acquires certain assets of the Top Air Company, including Top Air sprayers, Parker and Ficklin grain handling products, Better-Bilt manure handling products. The Ficklin and Better-Bilt brands and products are eventually archived to make room for other product lines.

The Top Air T-Tank pull-type sprayer receives a design overhaul with capacities up to 2400 gallons and booms up to 90ft.

Liberty skid-steers debut at ConExpo Con/Ag in Las Vegas, Nevada. With the agricultural economy beginning to boom in 2006, this product line and brand quickly fades into the sunset.

Unverferth releases the Seed Runner bulk tender with a self-filling conveyor design at the National Farm Machinery Show in Louisville, Kentucky. A patent issues in 2012.

A patent issues for a conveyor with sealing belt edges used on Seed Runner tenders and portable conveyors.

Unverferth X-Treme grain carts debut with an angled, front-folding design for greater unloading reach and height. Several patents issue in 2015.

The introduction of the Unverferth Seed Pro bulk box tender, All-Wheel-Steer header transport and Top Air sprayer with a steerable hitch at the Farm Progress Show.

The Brent Avalanche model 2096 with a 2,000 bushel capacity launches at the Farm Progress Show along with the Killbros SeedVeyor seed tender product line.

The company showcases the new Parker Seed Chariot seed tender at the Farm Progress Show.

The UHarvest data management system for grain carts debuts in conjunction with Raven Industries.

The company acquires property in Swift Current, Saskatchewan, to construct a new sales branch to service Western Canadian customers.

Unverferth introduces the NutriMax liquid fertilizer applicator, which brings the company into the fertilizer application market. In the same year, the 42"-wide Equalizer grain cart track system debuts.

The innovative Brent V-Series single-auger, side-folding grain cart launches and maximizes forward reach for enhanced unloading visibility.

The cover crop seeder for the Rolling Harrow conditioner debuts for a quicker and more economical solution to planting cover crop seed.

The company purchases the Blu-Jet product line from Thurston Manufacturing in Pender, Nebraska, which includes NH3 applicators among other products. In the same year, a new sales branch in Dublin, Texas opens, and is relocated to Lubbock, Texas, in 2021.

Unverferth acquires the Pro-Force dry fertilizer spreader product line from Force Unltd. in Oelwein, Iowa, to round out the company's fertilizer application offerings.

The Raptor strip-tillage tool launches with an innovative narrow fold design for an all-in-one solution for strip-tillage and fertilizer application from one manufacturer.

Introduction of the new generation of Brent Avalanche grain carts with an innovative reversible auger design for left- or right-hand unloading.

Unverferth Mfg. celebrates its 75th Anniversary and also purchases Orthman Manufacturing located in Lexington, Nebraska, which include 2 facilities that produces a large lineup of strip-tillage tools, bedlisters, cultivators and much more..

Though the company officially began in 1948 as L.G. Unverferth Mfg. Co., Lawrence (L.G.) and his son Richard Unverferth began innovating in the 1930s when they developed the Beet Blocker, a motorized tool for thinning sugar beets. Lawrence, who was a farmer by trade and mechanical by nature, invented this implement to help him and neighbors mechanize the monotonous process of thinning young beets to optimize yield. Richard and other family members were there to refine the tool for commercialization.

A patent for the Beet Blocker was issued to L.G. in 1936 who sold it to H.C. Rassmann in Denver, Colorado. Mr. Rassmann marketed them as Rassmann-Unverferth Sugar Beet Blocking and Thinning machines.

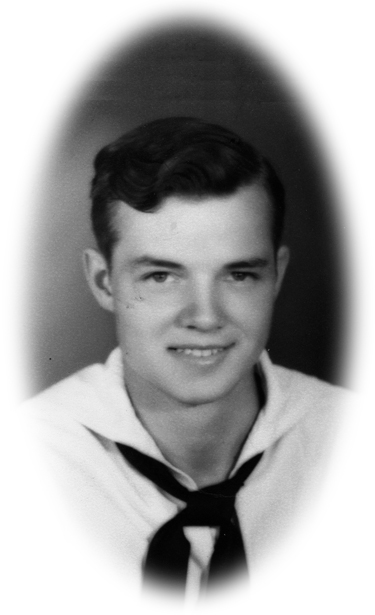

Richard enlisted in the Navy in January 1943 where he served on a submarine in the Pacific theatre during WWII. In 1947, knowing jobs would be scarce when he returned the following year, he and his father pooled their savings and secured additional funding with plans to officially launch the company as L.G. Unverferth Mfg. in 1948.

The Unverferth duo saw a need to help local farmers become more efficient, so they began manufacturing innovative combine shucker door control levers for Massey-Harris combines. After manufacturing enough to fill the trunk of a car on the family farmstead on Road 18, just south of Kalida, Richard set off across the Midwest selling these goods. The proceeds from these sales went towards securing raw materials for the next “trunkload” that would be made and sold in the same fashion.

In 1949, they introduced bolt-on, stovepipe hat-shaped wheel extensions for adding dual wheels to tractors. In addition to dual extensions, the company also began manufacturing dual wheels, all from the family’s farm. These products firmly established the company in the agricultural wheel business, which continues today. The family’s farming operation also contributed to sustaining revenue in the early years when sugar beets and tomatoes were grown.

To keep manufacturing employees busy during the off times of manufacturing, and to provide additional cash flow for the fledgling company, what eventually became Dick’s Restaurant in Kalida, Ohio was purchased in 1949. The Knotty Pine restaurant in Ft. Jennings and L&M restaurant in Ottawa also became part of the family business until their sale in the 1970s, when manufacturing was fully self-sustaining.

On July 7, 1951, Richard married Gladys Pugh who also became very involved in the business, doing just about anything that was needed. The couple lived above Dick’s Restaurant for a while after their marriage. Their eight sons, as they became old enough, also worked at the company in a variety of duties. Five of them eventually made a career with the company.

Unverferth Mfg. continued growing throughout the 50s and 60s by introducing new, innovative methods of attaching dual wheels to tractors and combines that included Over-the-Rim® and patented T-Rail® duals. The family farming operation continued growing sugar beets, tomatoes and grains. Manufacturing employees, including Richard, were often enlisted to help with planting duties and trucking during the busy harvest. In October, 1962, L.G. passed away due to complications from a stroke a year or so earlier.

In 1963, Richard purchased land at the current location to consolidate the several manufacturing and storage areas throughout the farm and in town as well as provide office space for the growing company. The 15,680 square foot building was completed in 1964 and the company became incorporated as Unverferth Mfg. Co., Inc. This new building helped fuel company growth by expanding dual wheel capacity and the addition of Turn-Right running gear with innovative steering.

In 1965, a neighboring dual wheel competitor, Hammer & Gump, became available from Ed “Coon” Hammer and Andy Gump of Miller City. They engineered the snap-on style of clamp-on dual hardware that is still used today. In addition to dual attaching hardware, the Hammer and Gump name was used on gravity boxes and running gear in the 70s.

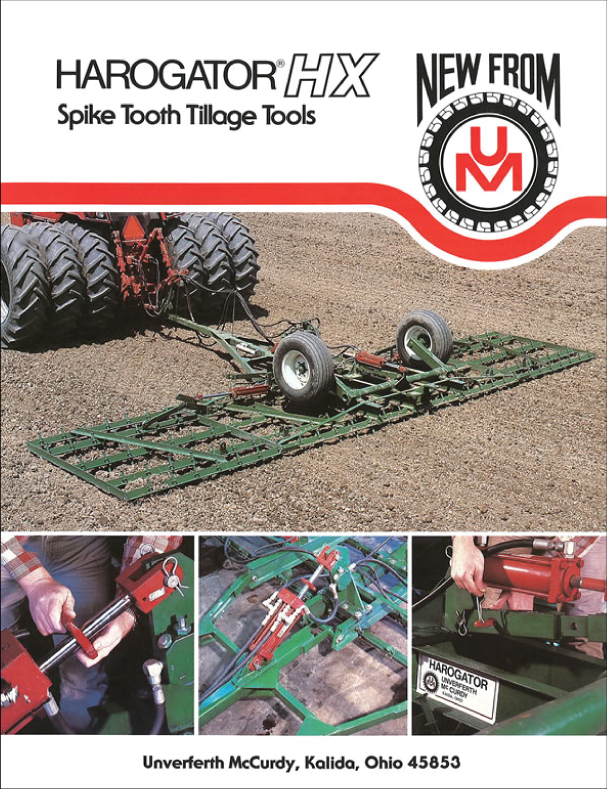

Unverferth Mfg. further expanded into the grain handling business in 1972 with the purchase of McCurdy Manufacturing in Ada, Ohio. The gravity boxes were coupled with the company’s running gear to supply dealers with complete grain wagon assemblies.

McCurdy also manufactured grain and fertilizer augers that mounted onto gravity boxes and trucks, chain elevators for moving bales into barn lofts and commercial refuse containers. Production of augers and gravity boxes transitioned by 1976 to Kalida and the Ada facility was sold. The McCurdy name evolved into Unverferth McCurdy and continued until the mid-80s when it was transitioned exclusively to the Unverferth name.

The purchase of Grover Manufacturing of Luckey, Ohio in 1979 advanced the company’s product line to include tillage equipment with the Harogator soil conditioner.

With the Harogator tillage line success, organic innovation soon led to other tillage products such as the Perfecta field cultivator, Cult-Planter, Rolling Harrow and Penetrator disk chisel and several bolt-on leveling attachments. When the Luckey plant was destroyed by fire in March, 1990, production was moved to Kalida which had greatly expanded manufacturing capacity by then. Though the pull-type and most mounted models were sunset shortly thereafter, the Harogator name lives on with a one-bar tillage attachment.

Unverferth Manufacturing grew westward with the acquisition of Brent Industry assets in Shell Rock, Iowa in 1988. This well-known and respected, Midwest-based grain cart and grain wagon line introduced Unverferth Mfg. to a broader range of dealers with an ever-expanding product line.

This facility has also grown throughout the years and today produces five different brands and several different styles of grain handling products. Pull-type sprayers and liquid and dry fertilizer applicators are also produced there today. The Brent name was also used over the years for the innovative CPC 2000 disc ripper with angle- and on-the-go depth adjustable disk gangs, the first of its kind, as well the HCV2000 field cultivator, Earthquake and Tremor tillage equipment.

Richard turned the reigns of president over to his eldest son, Steve, in 1992, and remained actively involved in the company as chief executive officer until his passing on February 26, 2004, due to pneumonia.

In the early 90s, conservation tillage was coming into the mainstream and a concept called zone-tillage was capturing the attention of many farmers. The system used three mirrored and opposed coulters on a toolbar to till a 6” to 10” seedbed zone into which the seed could be planted. It provided the conservation benefits of no-till along with the yields of conventionally tilled fields.

The Zone-Tillage lineup grew to include a pull-type Zone-Till cart with liquid fertilizer application, the Zone-Builder deep-till implement to eliminate compaction and a planter that could be pulled behind the Zone-Till cart for one-pass fertility and planting. With other tillage styles becoming more fashionable, the lineup was trimmed to the Zone-Builder subsoiler and stand-alone coulter attachments in the early 2000s with the Zone-builder implement continuing strong into our 75th year.

In 1993, the Kill family decided to sell Kill Brothers Company, a successful Delphos, Ohio-based manufacturer of grain handling, box augers and tillage products. Although Kill Brothers and Unverferth were fierce competitors for many years, the Kill family felt that Unverferth Mfg. would be the best buyer because of the family atmosphere. Today, the Delphos facility continues manufacturing a wide range of the company’s tillage, grain, seed and fertilizer application products and has greatly increased in size to 325,000 square feet from the original 80,000 square feet in 1993.

By the company’s 50th anniversary in 1998, product quality was further enhanced to stay ahead of the competition through major investments in state-of-the-art powder coating systems in Kalida and Shell Rock and a new paint system in Delphos. Investments in CNC machining and robotic welding cells were also made to provide higher-quality products. Investments such as these continue today with state-of-the-art fiber lasers, robotic fabrication and forming stations and collaborative robotics for manufacturing small parts.

The Brent Avalanche dual-auger grain cart also made its debut in 1998 with initially an 850 bushel model 884, followed by the 1,000 bushel model 1084 introduced shortly thereafter. This was the industry’s first cart with a pivoting vertical discharge auger that gave users the ability to quickly reposition the auger instead of the entire cart for enhanced unloading productivity.

The late 1990s and early 2000s saw a downturn in the farming economy due to lower crop prices and higher interest rates. To keep manufacturing people busy, the company launched a lineup of smaller tillage products for lower horsepower tractors know as Freedom tillage products. The company also purchased a skid-steer manufacturer, Hecla Industries, in 2000. In addition to the Patriot skid steer, the company also manufactured the Minuteman lineup of skid steer attachments. Production of these products was moved to Ohio where development work began.

In early 2001, Top Air Company of Cedar Falls, IA became a victim of the anemic farm economy and Unverferth purchased the remaining assets. The product lines included Top Air sprayers and seed conveyors, Parker and Ficklin grain handling products, Better-Bilt manure handling and Clay milking parlors. It was decided to maintain and expand the Top Air, Parker and Better-Bilt product offerings with manufacturing moving to Delphos and Shell Rock.

The Clay milking products were sold to Freeman Company in Canada, and the Ficklin brand sidelined. When the farm economy began taking off in 2006, thanks in part to the ethanol boom resulting higher commodity prices, the company focused on products that provided the volume and return necessary for its manufacturing needs and the Better-Bilt line faded away along with Minuteman products and the short-lived Liberty skid-steer loader.

In addition to the several companies that have fueled the company’s growth, new product innovations continued throughout the years. In 2006, the first self-filling seed tender, branded as the Unverferth Seed Runner, was introduced at the National Farm Machinery Show in Louisville, Kentucky. The show proved it to be an instant hit in the marketplace and quickly launched Unverferth Mfg. into a new market, eventually becoming one of the leading manufacturers of seed tenders. A patent was awarded for the design in 2012, with several more following, attesting to its innovation.

The Unverferth X-Treme grain cart with single, front-folding auger was introduced in 2009 that provided greater height and unloading reach in a front-folding design. The unique forward pitch design of the auger folded diagonally across the front and was awarded a patent a few years later.

With increasingly larger grain carts being produced, the company sought out ways to improve flotation on grain carts currently carrying up to 2,500 bushels. The idea was spawned to create a wider track belt and a pivoting undercarriage that pivoted both front and rear similar to the traditional track, but also pivoted side-to-side to help maintain the cart’s footprint over uneven terrain. Thus was born the Equalizer track system that made its debut in 2014.

Seeing the growth of in-season fertilizer placement and the need for well-built, long-lasting equipment for larger farmers, the NutriMax applicator was designed and introduced to the market in 2014. Farmer adoption was slow at first, but as the reputation of the machine’s narrow transport width, which earned a patent, high-speed application capabilities and durability, it quickly became the fertilizer applicator of choice among the larger growers.

With the rear-folding design of Brent corner-auger grain carts being in a solid market position, the move was made to further enhance unloading visibility by making the auger longer and angling it outward. Coupled with a four-way downspout, the V-series of corner-auger grain carts was born.

With a quest to continue robust growth, the search was on to find complementary fertilizer application equipment that would expand the company’s reach and growth. In early 2019, Blu-Jet products became available through the bankruptcy of Thurston Manufacturing in Pender, Nebraska. The assets were purchased by August and manufacturing was rapidly brought into the Unverferth fold for sales, support and manufacturing.

Shortly after, in January, 2020, the Pro-Force lineup of dry fertilizer spreaders became available from Force Unlimited in Oelwein, Iowa and were purchased. These two product lines and brands completed the company’s roundup of fertilizer application products to cover the full commercial fertilizer needs of any farmer or applicator- anhydrous and liquid to dry.

In 2021, after a few years of testing and refining, the Unverferth Raptor strip-tillage tool made a “virtual” debut due to cancellations of farm shows during the ongoing Covid-19 pandemic. This tool was designed with the need to create an ideal seedbed and provide needed fertility in the zone, which is where it’s best utilized by the crop. The wide adoption of GPS systems in tractors makes planting in the strips more easily replicated than it was using row makers used on the early Zone-Tillage products.

Throughout the years, Unverferth Manufacturing has maintained its family ownership, which contributes to the family atmosphere at its manufacturing facilities in Kalida and Delphos, Ohio, Shell Rock, Iowa, Lexington, Nebraska, and current sales branches in California, Georgia, Nebraska, North Dakota, Oregon, Texas and Ingersoll and Swift Current, Canada.

In 2023, there are 900-plus employees and over 1.3 million square feet of manufacturing space under roof, including recent building additions at all three manufacturing locations. The eight sales branches across the United States and Canada service our customers with high-use replacement parts and wheels for customers in those areas. The farming operation continues today with a corn/soybean/wheat rotation and continues serving as a testing ground for the company’s new designs.

New products being first offered for 2023 include the 98-series of Brent Avalanche grain carts with a host of new features, including increased auger reach and height, right-hand unloading and an all-new metallic black color, marking the 25th anniversary of this product.

With continued product innovation, Unverferth Mfg. and its employees are poised to continue the momentum built and nurtured by Richard and his father. The company continues the family ownership with Steve transitioning to chairman, Larry to president, and Dave to vice president of operations. The fourth generation is also taking on greater responsibilities in management and daily company operations.

The history of Unverferth Mfg. story is only complete by acknowledging the many dedicated people who have contributed to the culture of growth and innovation over the decades. To paraphrase Richard Unverferth from a 1990’s talk at the annual Christmas luncheon, ‘the investments in buildings, equipment and computers don’t make the products without the people. They are our most important asset!